ESS Panel Concept of Operation

The ESS Panel is a revolutionary patent-pending energy-saving technology designed to reduce energy costs and optimize electrical network efficiency significantly. This section delves into how the ESS Panel works.

1. Understanding Power Consumption

Electrical equipment relies on two distinct types of power:

- Active Power (kW): Measured in kilowatts (kW), this is the essential power that delivers real work. It’s the power utilized by any equipment to operate, like running motors or lighting lamps.

- Reactive Power (kVAR): Measured in kilovar (kVAR), reactive power creates a burden on the electrical system without directly contributing to work. It arises from components like transformers and motors that require an electromagnetic field to operate.

Imagine the electrical system as a highway. Active power represents the cars transporting goods, while reactive power is like traffic congestion – it doesn't deliver anything valuable but creates an additional strain on the system. High levels of reactive power can lead to inefficiencies and potential equipment damage.

2. The ESS Panel Structure

The ESS Panel Structure is similar to the Power Factor Correction (PFC) Panel. While the ESS Panel shares structural similarities with PFC panels, their functionalities are different. PFC panels focus on improving efficiency by reducing reactive power (kVAR), which optimizes system performance but doesn’t directly lower overall energy consumption (kWh).

ESS panels directly target overall energy use (kWh), along with other benefits, resulting in greater cost savings and a more sustainable energy footprint.

3. The ESS Panel and It’s Core Innovation

The ESS Panel actively reduces overall energy consumption alongside improving the power factor.

At the heart of this innovation lies a proprietary ionic treatment process applied to the ESS panel’s capacitors. This unique treatment imbues them with remarkable properties, transforming them from passive components to active contributors to energy savings.

Our ionic treatment process for capacitors is a complex procedure that imbues them with unique properties. This advanced method guarantees exclusivity because it’s impossible to replicate. Even if someone dismantles the treated capacitor, the key elements of our treatment technique remain hidden.

These specially treated capacitors function as a current source within the electrical network. They inject high active current, effectively reducing the current drawn from the source. This results in a significant reduction in kWh usage, leading to real cost savings. Additionally, the ESS Panel improves power factor, optimizing the overall efficiency of your electrical system.

4. Understanding the Science Behind the ESS Panel

To grasp the ESS Panel's operation, let's explore a familiar concept: redox reactions.

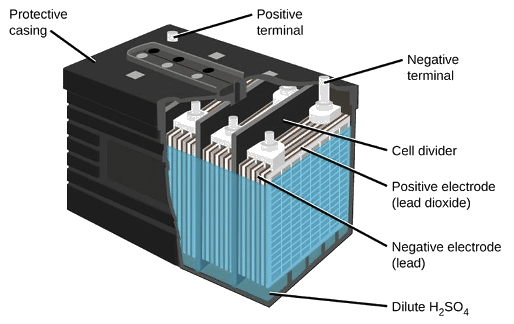

Redox reactions involve the transfer of electrons between chemicals. A classic example is a lead-acid car battery. Inside a lead-acid battery, lead and lead oxide plates are submerged in sulfuric acid. During discharge, electrons flow from the lead plate (oxidation) to the lead oxide plate (reduction), generating electricity.

An example is a lead-acid car battery.

Eventually, the reaction reaches a point where all the lead has been oxidized, and all the lead oxide has been reduced. The battery then needs to be recharged. Recharging reverses this process, forcing the lead plate to be re-oxidized and the lead oxide plate to be re-reduced, restoring the battery’s ability to deliver power.

The ESS Panel leverages a similar principle for energy storage. While not a traditional battery, it utilizes the concept of redox reactions within its design. Through a special process, we treat one plate of the capacitor like an oxidized electrode. When connected to a power source, the ESS undergoes a controlled internal redox reaction during charging and discharging. This allows the ESS to act as a source of current that can be fed back into the network, effectively functioning as an additional power source.

5. The Power of Active Current Injection

The ESS panel’s specially treated capacitors inject high active current into the internal network. This, in turn, reduces the current drawn from the source, leading to direct cost savings. Additionally, these capacitors improve your power factor for overall system efficiency.

As the power formula (P = V x I x cosφ) indicates, if the voltage remains constant and the power factor is increased, the current decreases proportionally. This means that there would be no reduction in kilowatt-hours (kWh) consumption.

Imagine a scenario where a facility has a load of 36 amperes, a voltage of 220 volts, and a power factor of 0.8.

Without capacitors: P = 220 x 36 x 0.8 = 6,336 watts

With standard capacitors: P = 220 x 32 x 0.9 = 6,336 watts

- Even though the current lowers (to 32 amperes) and the power factor improves (to 0.9), the kWh consumption remains the same at 6,336 watts. Standard capacitors don’t impact kWh consumption, they only address reactive power.

With ESS Panel unique capacitors:

P = 220 x 10 x 0.99 = 2,178 watts

The unique capacitors within the ESS panel inject high active current, effectively reducing the drawn current from the source to a much lower value (e.g., 10 amperes) while maintaining a high power factor (e.g., 0.99). This significantly reduces power consumption to 2,178 watts.

In summary, the ESS Panel significantly reduces energy consumption, improves power factor, and optimizes electrical network efficiency, resulting in substantial cost savings and environmental benefits. This innovative technology offers a sustainable and economically viable solution for various Industrial, Commercial, and Residential Facilities.